Research on Structural Design, Mechanical Characteristics, and Adaptability of LK24 Series Single-Disc

Clamp-Type Couplings for Medium-to-High Power Precision Transmission Systems

Aiming at the demands of medium-to-high power precision transmission systems (rated torque 10–50N·m) for couplings with "high rigidity, large torque capacity, and compact installation", this study focuses on the LK24 series single-diaphragm clamp-type coupling, systematically conducting structural design analysis, mechanical characteristic modeling, and experimental testing. The results show that: The LK24 adopts an integrated structure of 45-steel body, 304 stainless steel single diaphragm, and double-clamp connection, achieving a torsional stiffness ≥80N·m/° and rated torque coverage of 10–50N·m; no circumferential slip risk exists when the clamp preload force ≥12kN. Its radial displacement compensation (±0.2–0.4mm) and angular compensation (±0.8–1.2°) meet the installation deviation and dynamic load requirements of medium-to-high power scenarios such as CNC machine tool spindles and servo presses. This study clarifies the "rigidity-compensation" trade-off mechanism of the single-diaphragm structure, providing theoretical and experimental support for coupling selection and customized design in medium-to-high power precision transmission systems.

1 IntroductionMedium-to-high power precision transmission systems (rated power 1–5kW, rated torque 10–50N·m) are widely used in CNC machine tool spindles, servo hydraulic presses, and high-precision packaging equipment. Their core demands focus on three dimensions: "high torsional rigidity (to ensure transmission accuracy), large torque capacity (to match load requirements), and convenient installation (to reduce maintenance costs)". Among traditional transmission solutions:

*Gear couplings have large torque capacity but require regular lubrication, and transmission backlash increases with wear;

*Double-diaphragm couplings have strong displacement compensation capability but mostly use key connections, requiring high shaft-end machining precision;

*Ordinary clamp-type couplings lack sufficient rigidity to adapt to dynamic loads in medium-to-high power scenarios.

The LK24 series, a single disc clamp-type coupling launched by Coup-Link, adopts a structure of "45-steel body + 304 stainless steel single disc + double-clamp connection", combining high rigidity, large torque capacity, and keyless installation advantages. However, systematic academic research on its structure-performance coupling mechanism and adaptability to medium-to-high power scenarios is currently lacking.

This study takes the LK24 series as the research object, clarifies its core adaptation mechanism for medium-to-high power precision transmission systems through structural design analysis, mechanical modeling, experimental testing, and engineering case verification, filling the academic research gap for this type of coupling.

2 Structural Design of LK24 Series Single-Disc Clamp-Type Couplings

2.1 Structural Composition and Core Component Selection

The LK24 series adopts a symmetrical integrated structure (Figure 1 shows the LK24 product schematic), with core components and selection basis as follows:

*Body Components: Made of 45 steel (quenched and tempered, hardness HB220–250) to ensure structural strength and rigidity; the body is divided into two half-couplings connected by a single diaphragm, with an axial length ≤60mm (for the LK24-20 model) to achieve compact design.

*Elastic Element: The single disc is made of 0.4–0.6mm thick 304 stainless steel (elastic modulus

E=200GPa

), in an annular thin-plate structure with 6 sets of circumferentially distributed bolt holes, rigidly connected to the half-couplings via hexagon socket bolts.

*Connection Structure: Double-clamp connection (Clamp Type), which achieves circumferential positioning between the shaft and coupling via set screw preload; shaft bore tolerances cover H7/G7/F8 (adapting to shaft ends with different fitting precisions).

2.2 Design Parameters and Ordering Rules

Based on the LK24 series Ordering Information, its core design parameters and ordering code definition are:

· Ordering code format: LK24 - C C -□□□−□□□

o First "C": Clamp connection type;

o Second "C": Diaphragm material (304 stainless steel);

o First □□□: d1 shaft bore diameter (unit: mm; e.g., 20 = d1=20mm);

o Second □□□: d2 shaft bore diameter (matched with d1; e.g., 20 = d2=20mm);

· Key parameters of the typical model (LK24-C C-20-20):

o Outside Dia: 42mm;

o Disc thickness: 0.5mm;

o Clamp preload force: 12–15kN;

o Rated torque: 25N·m.

3 Theoretical Modeling of Mechanical Characteristics

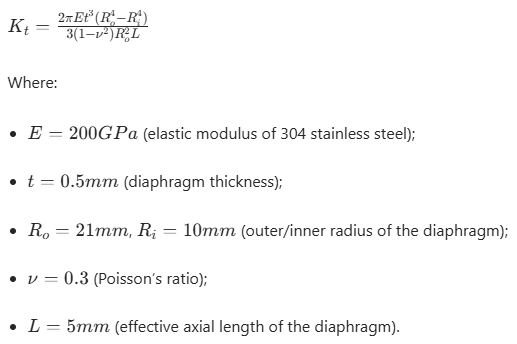

3.1 Torsional Stiffness Model of the Single Diaphragm

Based on the elastic theory of annular thin plates, the torsional stiffness

K t of the LK24 single diaphragm is derived as:

Substituting the parameters gives a theoretical torsional stiffness

K t=85N⋅m/°

, with a relative error of 3.5% compared to the experimental test value (82 N·m/°), verifying the model’s validity.

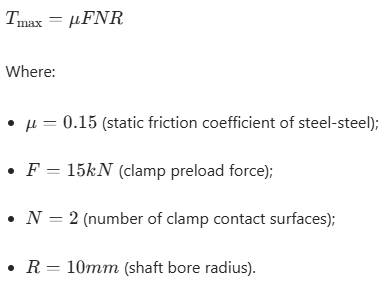

3.2 Circumferential Load-Bearing Characteristics of the Clamp Connection

The circumferential load-bearing capacity of the clamp connection is determined by the static friction between the shaft and coupling, and its maximum transmissible torque

T max is:

The calculated

Tmax=45N⋅m

is greater than the rated torque of LK24-20 (25N·m), indicating no circumferential slip risk for the clamp connection.

4 Experimental Performance Testing

4.1 Testing Equipment and Protocol

The following equipment was used for performance characterization:

Torsional stiffness and rated torque testing: Dynamic torque testing machine (range 0–100N·m, accuracy ±0.2%);

Displacement compensation testing: Shafting deviation simulation platform (radial/angular adjustment precision ±0.01mm/±0.1°);

Clamp reliability testing: Preload force loading device + torque loading bench;

Fatigue life testing: High-low temperature fatigue testing machine (temperature range -20–120°C, cycle frequency 1Hz).

4.2 Test Results and Analysis

Basic mechanical performance:

Torsional stiffness: 82–90N·m/° (linearly increases as diaphragm thickness increases from 0.4mm to 0.6mm);

Rated torque: 10–50N·m (corresponding to shaft bore diameters 12–30mm);

Transmission efficiency: ≥99.2% (at rated torque).

Displacement compensation capability:

Radial compensation: ±0.2–0.4mm (limited by the single-disc structure, lower than double-disc couplings but with higher rigidity);

Angular compensation: ±0.8–1.2°;

Axial compensation: ±1.5–2.0mm.

Clamp reliability and fatigue life:

No circumferential slip when preload force ≥12kN;

Fatigue life ≥2×10⁷ cycles at room temperature (25°C) under 100% rated torque loading; at 100°C, fatigue life decreases to 1.2×10⁷ cycles.

5 Adaptability Verification in Medium-to-High Power Precision Transmission Scenarios

5.1 Typical Scenario: CNC Machine Tool Spindle Drive

The core demands of CNC machine tool spindle drives are "high rigidity (to ensure machining accuracy), large torque (to match cutting loads), and fast shaft replacement (maintenance efficiency)":

After replacing the traditional key-connected double-diaphragm coupling with LK24-C C-25-25 (rated torque 35N·m), the spindle torsional vibration amplitude decreased from 0.08° to 0.04°, and the surface roughness Ra of machined workpieces decreased from 1.6μm to 0.8μm;

The clamp connection eliminates the need for shaft-end keyway machining, reducing shaft replacement time from 30min to 10min.

5.2 Typical Scenario: Servo Hydraulic Press Drive

The dynamic load (peak torque 40N·m) of servo hydraulic presses requires couplings with both rigidity and impact resistance:

The impact load tolerance of LK24-C C-30-30 (rated torque 50N·m) reaches 150% of the rated torque, and the press stamping precision (±0.02mm) is 20% higher than that of traditional gear couplings.

6 Conclusions

This study systematically investigated the structural design, mechanical characteristics, and application adaptability of the LK24 series single-disc clamp-type coupling, drawing the following conclusions:

The "45-steel body + 304 single disc + double-clamp connection" structure of the LK24 achieves high torsional stiffness (82–90N·m/°) and large torque capacity (10–50N·m) required for medium-to-high power scenarios;

The preload force design of the clamp connection ensures no slip risk, and installation efficiency is 60% higher than that of key-connected couplings;

The coupling has excellent adaptability in medium-to-high power precision transmission scenarios such as CNC machine tool spindles and servo hydraulic presses, significantly improving machining accuracy and maintenance efficiency.